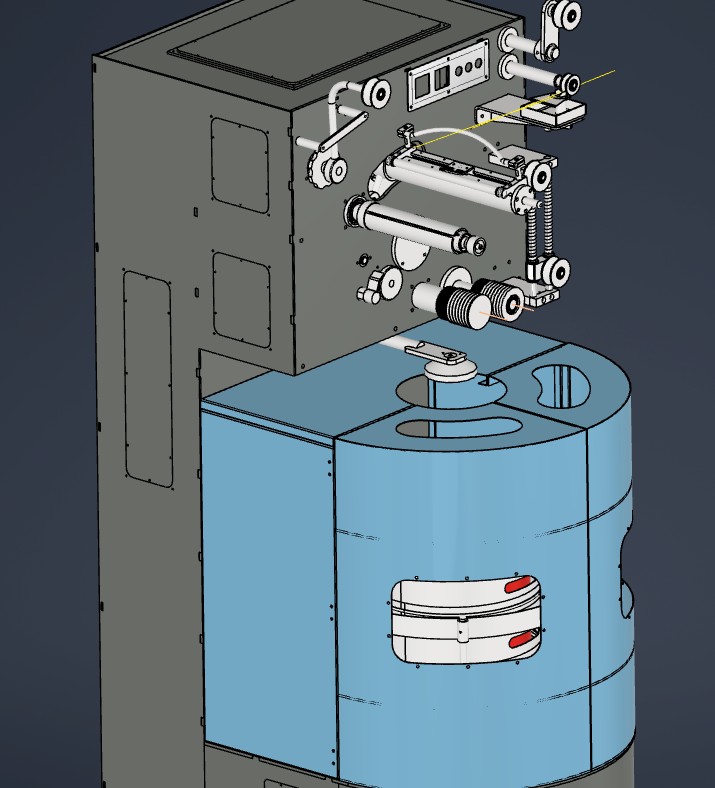

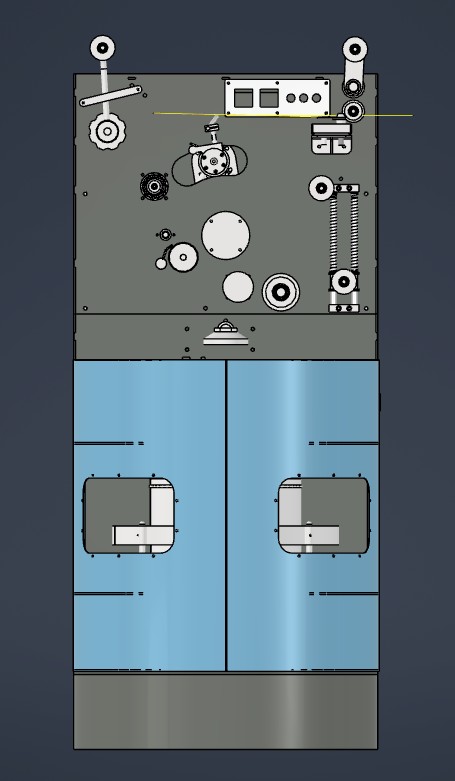

The CIRMANTECH TWISTLAB 1 is a single-spindle, high-precision twisting machine designed to pave the way for innovation in the textile industry. It frees you from the rigidity and high cost of large-scale production lines, offering unparalleled flexibility for your R&D activities, quality control tests, and boutique production needs.

Developed with Cirmantech's experience in industrial machine manufacturing, the TWISTLAB 1 allows you to process yarns made from PP Raffia, synthetic monofilament, multifilament, and other high-performance synthetic polymers with precise twist control. Whether you are developing a new hybrid yarn or testing raw material from a new supplier for your production, the TWISTLAB 1 is your most reliable laboratory partner.

| Model | CIRMANTECH TWISTLAB 1 (CT-TL1) |

|---|---|

| Number of Spindles | 1 |

| Processable Materials | PP Raffia, Synthetic Monofilament, Multifilament |

| Twisting Denier Range | 4,000 – 27,000 Denier |

| Mechanical Twisting Speed | Up to 8,000 TPM (based on two twists per turn) |

| Production (Winding) Speed | Up to 200 m/min |

| Twist Direction | S & Z (digitally selectable) |

| Twist Range (TPM) | 10 - 40 TPM (twists per meter) |

| Control System | Mechanical Control (Standard) / PLC and 7" Touchscreen HMI (Optional) |

| Winding Unit | Servo motor-assisted precision winding tension control |

| Data Management | Recipe Saving and Production Data Tracking (Optional) |

| Output Bobbin Type | With and Without Bobbins (Cylindrical or Conical - optional) |

| Maximum Bobbin Diameter | 310 mm |

| Winding Start Diameter | 60 mm |

| Bobbin Weight | Varies according to winding length |

| Motor Power | 1.5 kW or 2.2 kW (varies by winding length) |

| Special Production | Oiled Bigbag Sewing Thread Production Kit (Optional) |

| Electrical Requirement | 380V, 50/60 Hz, 3 Phase |

| Machine Dimensions (WxDxH) | ~0.8 m x 1.2 m x 1.8 m |

For more information about TWISTLAB 1 or for a custom solution for your project, contact us.